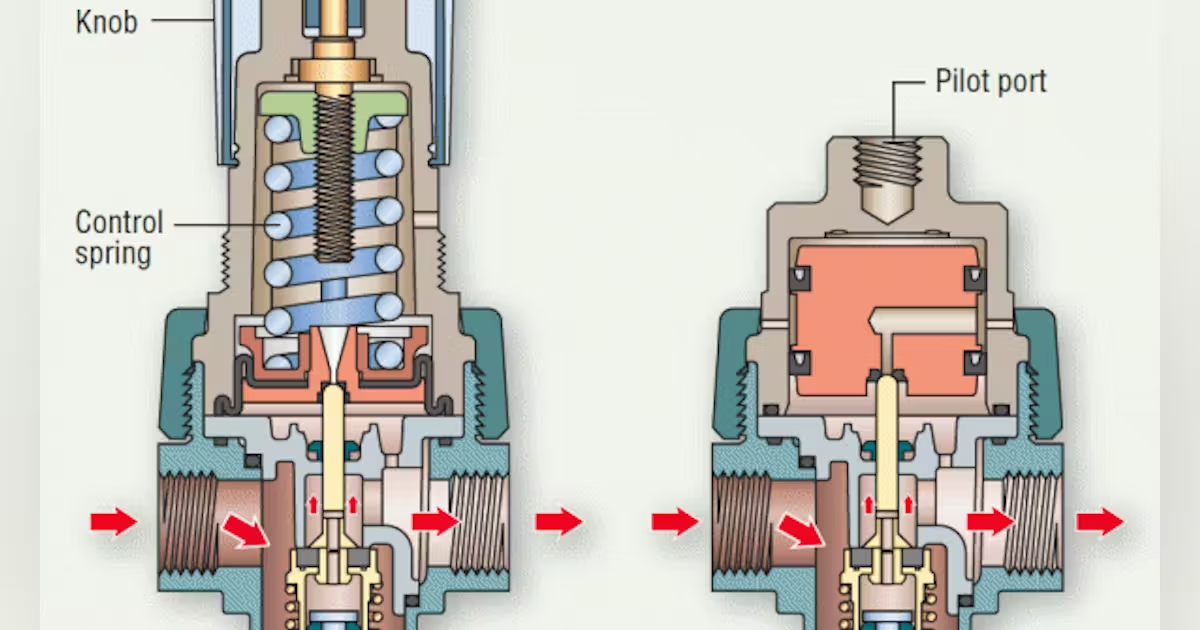

For the accurate working of pneumatic tools, an air pressure regulator is considered an integral component. This device helps the user to operate pneumatic systems or tools safely and efficiently. An electric air pressure regulator reduces the air pressure and maintains a steady flow of air regardless of pressure fluctuations.

Keep in mind the success of the pneumatic tool depends on the use of the right type regulator. Nowadays, they are available in various types, sizes and shapes. They perform the same functionality but they can not perform well in any pneumatic tool. Because each type of pneumatic tool requires a specific type of electronic pressure regulator that can fulfil its requirements.

Below we have listed three main types of the air pressure regulator:

Precision Air Regulators:

This type of air pressure controller is widely used in applications where accuracy is the main concern for the users and they can not comprise on accuracy such as in OEM applications, labs, medical devices etc. They are the perfect options for sensitive instruments and the industrial sector.

The thing that makes them unique is their accuracy and sensitivity. You can consider sensitivity as the ability of the electric air pressure regulator to react to pressure changes. For instance, a regulator has a sensitivity of 1/8 water column. This means if there will be a change happen about 0.0045 PSI in the pressure, then the regulator will automatically make a correction and make the output pressure equal to the set value.

Filter Regulators:

When the protection of the equipment or tool is the priority for the users then a filter regulator comes in handy. This type of digital pressure controller reduces the pressure, keeps it equal to the set point and keeps the airlines clean. This is essential to keep the airlines clean from moisture and particles so that the pneumatic system or tool can outperform. They all have the same regulation principle.

In this type, the air is passed through the filter which helps to remove moisture and other dust particles from the air. This type of electric air pressure regulator is good for expensive pneumatic tools. As it provides effective control over air pressure and also keeps the pneumatic tools or equipment safe.

This type of regulator is widely used in places where the user has to handle expensive gases such as compressed air. It reduces the risk of leakages and the pressure going down from the set limit by removing dust particles from the air supply. Because these particles can be very dangerous for the pneumatic tool or the pipeline. But the presence of a filter regulator removes all the particles and keeps the air clean for the improved performance of the system. In this way, it also enhances the lifespan of the system.

General Purpose Regulators:

A general-purpose regulator is a good option when the cost is the priority. That’s why, this type of digital air regulator is commonly found in the fluid power industry. The presence of a general regulator in a system surely reduces the consumption of the air as well as the electricity bill. They are basically designed to provide the maximum flow capacity while keeping the pressure value equal to the user-defined value. They are a perfect choice for individual service lines.

This type of regulator is commonly found in most of the applications around us because of its cost-effectiveness and precise results. A pressure regulator is not only used to regulate the fluid or gas at a precise pressure but to keep the fluid system safe and to enhance the efficiency and performance of the system. As it lets the system use the accurate amount of the fluid gas or air for performing a specific task as per the need.

Final Words:

Today, electronic regulator comes in various types and all of them differ from each other because they are designed to fulfil the requirements of different pneumatic systems or tools. But all of them perform the same functionality of reducing the air pressure. So to get the optimal performance from the pressure regulator, you must check out the requirement of the system and match them with the specifications of the electric air pressure regulator before making a purchase.